A guide for growing eCommerce brands

Growing your eCommerce business is exciting – sales are climbing, your product line is expanding, and you’re building a loyal customer base. But if you’re still fulfilling orders from your premises or warehouse, there often comes a pivotal moment when in-house order fulfillment starts holding your business back, rather than supporting its growth. That’s when exploring 3PL ecommerce fulfillment and outsourced fulfillment becomes essential.

This guide will help you recognize the critical signs that it’s time to consider partnering with a third-party logistics (3PL) provider for your fulfillment needs. We’ll explore the key warning signals, examine industry benchmarks, and provide you with a framework to make this important decision from a position of strength rather than desperation.

Signs your brand needs outsourced fulfillment

The hidden costs of staying in-house too long

The most telling indicator that your in-house fulfillment is hampering growth is when your delivery standards begin to decline. Today’s consumers have sky-high expectations – approximately 90% of shoppers now expect two- or three-day shipping as standard, and 32% will abandon their cart if delivery times are too long.

When your internal operations can no longer guarantee consistent delivery windows, outsourcing fulfillment may be the solution.

Research shows that 41% of customers won’t return to a retailer after experiencing late deliveries, while 57% would be hesitant to purchase again if an order arrives damaged. These statistics underscore a harsh reality: poor fulfillment performance directly impacts your customer lifetime value and brand reputation.

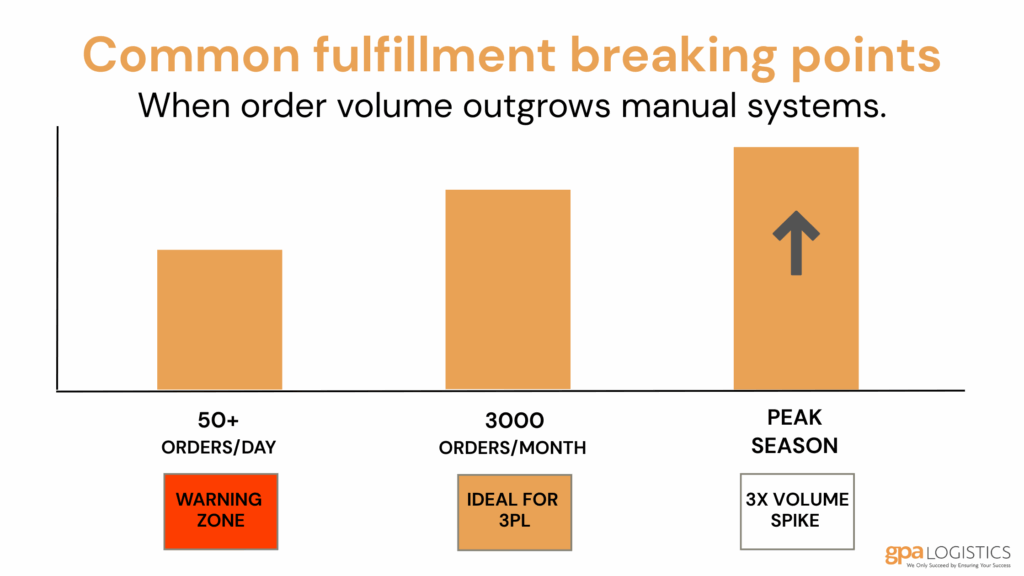

The order volume tipping point for Outsourced Fulfillment

Many eCommerce business owners find their in-house fulfillment operations become unmanageable around 50-100 orders per day. This threshold varies depending on your product complexity and team size, but it usually represents the point at which manual processes become unsustainable. At this point, outsource fulfillment through reputable eCommerce fulfillment companies becomes cost-effective and scalable.

Peak seasons amplify these challenges significantly. During Q4, order volumes can multiply several times over, creating bottlenecks that overwhelm even well-organized internal operations. The holiday season consistently reveals gaps between retailer expectations and actual performance, with many companies struggling to meet customer delivery expectations, despite feeling confident beforehand.

Rising costs that eat into your margins

High shipping costs often serve as the financial wake-up call for growing businesses. When your annual shipping expenses reach several thousand dollars, the economies of scale offered by 3PL ecommerce fulfillment and key outsourced fulfillment providers become increasingly attractive.

3PL providers can offer bulk discounts and negotiated carrier rates that individual businesses just can’t access. Their structured pricing typically includes inventory receiving, storage fees, pick and pack charges, plus shipping costs that are often 10-50% lower than standard retail rates.

Consider the hidden expenses of in-house fulfillment: warehouse rent, utilities, insurance, equipment, staff wages, and the opportunity cost of your management time. These costs compound as you scale, often making outsourced fulfillment look more economical than it may have initially.

Strategic inflection points: when most businesses make the switch

Revenue and volume benchmarks

While specific thresholds vary by industry, patterns emerge from businesses that have successfully transitioned to 3PL partnerships:

Order volume indicators

- 50+ orders per day: Manual processes become unmanageable.

- 3000+ orders per month: The minimum threshold where 3PL economics make sense.

- Seasonal spikes of 3x or more: Peak volumes that typically overwhelm in-house operat

Financial triggers for outsourced fulfillmen

- $5M plus in annual revenue: Revenue levels that often correlate with substantial order volumes.

- $1,000+ in monthly shipping costs: The point where 3PL bulk rates become attractive.

- Rising fulfillment costs as a percentage of revenue: When logistics expenses start eroding your margins.

Operational readiness signals for outsourcing fulfillment

Beyond numerical thresholds, certain operational challenges indicate that you’re ready for outsourcing:

Space and infrastructure limitations

When inventory overflows your current space, you face the choice between expanding your warehouse or partnering with a 3PL. Commercial warehouse rental costs can range from $15-$30 per square meter annually, plus utilities, insurance, equipment, and staff expenses, so this can be a pricey option.

Labor challenges

The logistics industry faces significant workforce shortages, with warehouse job openings projected to reach 2.1 million by 2030. Labor costs can account for 60-65% of fulfillment operating budgets, and seasonal staffing presents ongoing challenges for smaller operations.

Technology gaps

Fulfillment errors often stem from disconnected systems rather than warehouse mistakes. Many growing businesses operate with fragmented technology – separate platforms for sales, shipping, inventory tracking, and accounting – creating multiple failure points that multiply as order volume increases.

The strategic advantages of timely outsourcing

Scalability without infrastructure investment

Partnering with a 3PL provides immediate access to scalable infrastructure without capital investment. This enables rapid growth during successful campaigns or seasonal surges, without the risk of overinvestment in permanent capacity.

Modern 3PL providers offer advanced technology integration, multi-channel support, and real-time visibility that would be prohibitively expensive for individual businesses to develop. These capabilities often exceed what even well-funded in-house operations can provide.

Focus on core competencies

Outsourced fulfillment allows you to concentrate on activities that directly drive growth: product development, marketing, customer acquisition, and strategic planning. This focus often accelerates business development beyond what improved fulfillment efficiency could provide.

Delegating fulfillment operations eliminates a major source of operational stress, allowing leadership teams to maintain strategic perspective during growth phases. As Daniel Rotman, founder of pet products brand PrettyLitter said, outsourcing operations was “core to growing, scaling and exiting [nine-figures] in a short period of time.”

Geographic expansion capabilities

3PL networks provide immediate access to multiple markets without establishing local infrastructure. This geographic flexibility becomes increasingly important as businesses expand beyond their initial markets, with many providers offering international capabilities that would be impossible for individual businesses to replicate.

How to decide: should you outsource order fulfillment?

Conduct your financial analysis

- Before making the decision on whether or not to outsource, conduct a comprehensive cost comparison:

Calculate true in-house costs including rent, labor, equipment, utilities, insurance, and the opportunity cost of management time. - Get detailed 3PL quotes for your specific volume and service requirements.

- Factor in growth projections to understand costs at different scale levels.

- Consider seasonal variations and peak capacity requirements.

- Include hidden costs like fulfillment errors, customer service issues, and delayed shipments.

Assess operational readiness

Evaluate your business’s readiness for a 3PL partnership:

- Order volume consistency: Do you have predictable monthly volumes that meet 3PL minimums

- Inventory management maturity: Are your inventory data and processes accurate enough for seamless integration

- System integration capabilities: Can your current platforms connect with 3PL systems?

- Customer service standards: Do you have protocols for handling fulfillment-related inquiries

- Returns processing: How complex are your return requirements?

Timing considerations

The optimal timing for outsourcing often aligns with:

- Pre-peak season preparation: Starting 6+ months before holiday seasons.

- Post-funding rounds: When growth acceleration is planned.

- Geographic expansion initiatives: Requiring new market access.

- Product line diversification: Increasing operational complexity.

- Management bandwidth limitations: When fulfillment distracts from strategic focus.

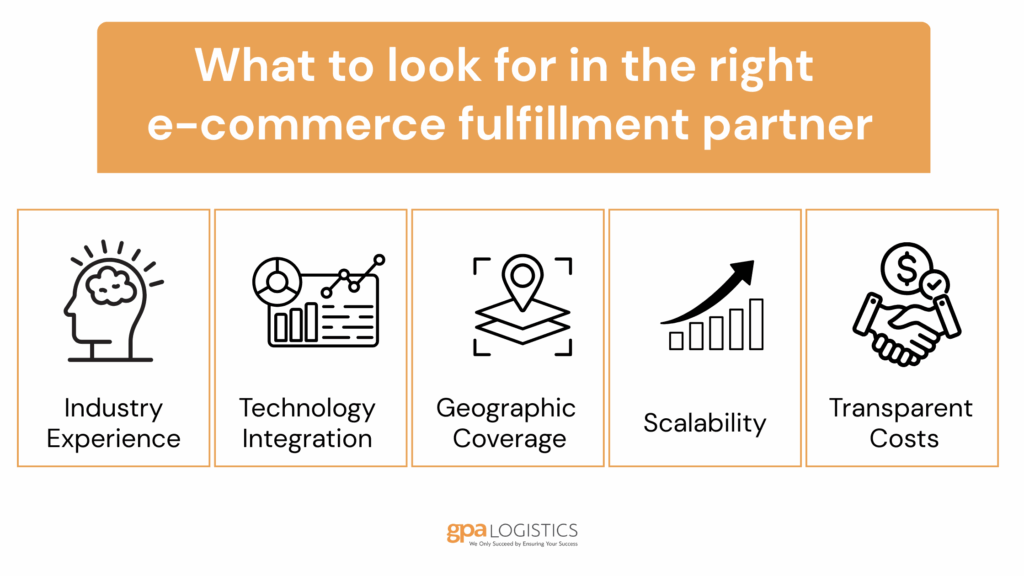

The path forward: choosing the right eCommerce fulfillment company or 3PL

When evaluating potential partners, consider these critical factors:

Experience in your industry: Look for providers with expertise in your product category who understand your specific packaging, storage, and shipping requirements.

Technology integration: Ensure seamless integration with your existing eCommerce platforms and the ability to provide real-time inventory and order visibility.

Geographic coverage: Choose a provider whose warehouse network aligns with your customer distribution and growth plans.

Scalability: Verify their ability to handle your peak volumes and seasonal fluctuations without service degradation.

Cost structure: Understand all fees, including setup costs, monthly minimums, and any additional charges for special services.

Embrace growth through strategic outsourcing

The decision to outsource fulfillment represents a strategic turning point in your business evolution. Rather than viewing it as losing control, successful brands recognize outsourcing as gaining access to specialized expertise, scalable infrastructure, and strategic focus.

Businesses waiting too long to make this transition often struggle with operational inefficiencies, customer satisfaction issues, and management distraction that ultimately limit growth potential. Conversely, companies that proactively partner with 3PLs position themselves for sustainable scaling while maintaining the personalized service that defines their brand.

As the world of eCommerce continues to change, the question isn’t whether to outsource fulfillment, but when to make the strategic move that unlocks your brand’s next phase of growth.

By understanding the warning signs and benchmarks outlined in this guide, you can make the outsourcing decision from a position of strength rather than desperation, ensuring a smooth transition that accelerates, rather than disrupts, your growth trajectory.

Ready to explore outsourced fulfillment for your growing eCommerce brand?

The team at GPA Logistics specializes in helping medium and large eCommerce businesses scale their operations through strategic fulfillment partnerships.

Schedule a discovery call with our founder Bill Drummer to discuss how outsourcing fulfillment could unlock your brand’s next growth phase.

Q&As

What is eCommerce fulfillment?

eCommerce fulfillment is the process of receiving, storing, picking, packing, and shipping online orders to customers. It includes inventory management, order processing, shipping coordination, and handling returns.

What are the 4 types of fulfillment?

- In-house fulfillment: the seller handles all logistics internally.

- Third-party fulfillment (3PL): a specialized provider manages storage, packing, and shipping.

- Dropshipping: the manufacturer or supplier ships orders directly to customers.

- Hybrid fulfillment: A combination of in-house, 3PL, and/or dropshipping methods.

What is outsourcing and why would a company choose to outsource?

Outsourcing is when a company hires an external provider to handle specific tasks or operations. Businesses outsource to reduce costs, access specialised expertise, scale more quickly, enhance efficiency, or focus on their core activities.

What does it mean to outsource order fulfillment?

Outsourcing order fulfillment means hiring a third-party logistics (3PL) provider to handle warehousing, packing, shipping, and returns.

Is outsourcing a good or bad thing?

Outsourcing can be very beneficial when used strategically. It’s “good” when it improves efficiency, saves time, and supports growth. It may be “bad” if it’s done without proper vetting or leads to loss of control over key operations.

What is the difference between in-house and outsourcing in eCommerce

In-house fulfillment is managed entirely by the seller using their own team, space, and tools.

Outsourcing involves a third-party provider who handles fulfillment tasks externally.

Key differences include cost structure, control, scalability, and resource demands.